How to set up and run a small scale cooking oil refining machine?

Small scale cooking oil refining machine

Main features of small scale cooking oil refining machine:

1.This equipment is easy operation.

2.It needs small area.

3.The oil product is good-quality.

4.It is suitable for intermittent animal and vegetable oil refining.

5.The oil needed to be refined per day is below 30 tons.

Small scale cooking oil refining machine in our factory

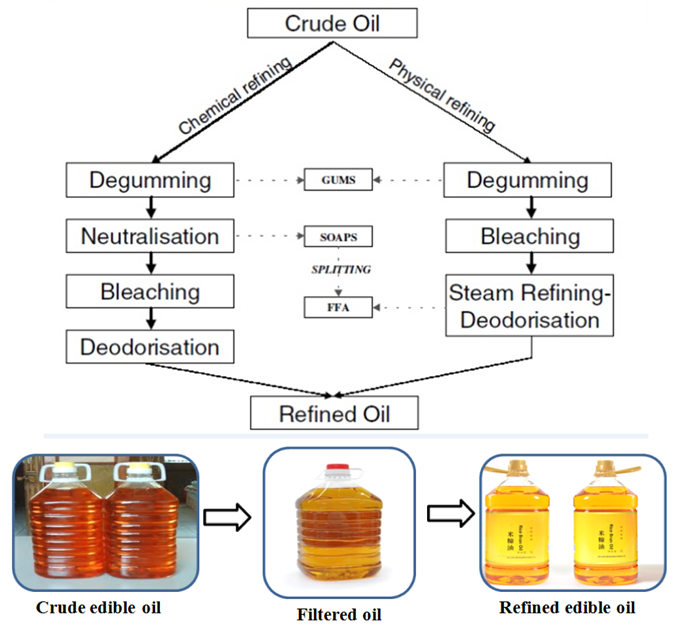

Technological process of small scale cooking oil refining machine:

1. It's a kind of intermittent small senior edible oilrefining equipment .

2. This is the special equipment for degumming,deacidification,decoloration,deodorization(senior edible oil,salad oil).

3.The complete set of small scale cooking oil refining machine includes heat conduction oil furnace,steam generator.It can process chemical refining without purchasing other pots.

4.Because deodorized tea seed oil,rice bran oil and corn germ oil etc. are with much fat or wax,they should be further dewaxing and degrease.

Small scale cooking oil refining machine with physical and chemical refining

1. Degumming: Removing the phosphatide by adding hot water, when phosphatide meets hot water, it will become bigger and bigger, then out of tanks.

2. Deacidification: Removing the FFA by add alkali liquor (for taking neutralization reaction).

3. Decolorization(Bleaching): Remove the pigment by adding bleaching earth( it has strong adsorption of pigment), and the remaining bleaching earth will be filtrated by leaf filter.

4. Deodorization: Remove the oxide, solid particle and volatile gas.

Application area:

Plant oil,such as palm oil,soybean oil,rice bran oil etc,animal oil,oil materials with high acid value and more impurities.

- Prev:What is extraction process?

- Next:Why palm oil mill plant need to close to palm fruit plantation?

Leave A Message

If you wanna to get more details about How to set up and run a small scale cooking oil refining machine? . you can send E-mail to oilmachine@doinggroup.com . And you also can leave a message in below form. We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

Contact us

- Phone: 0086 13526627860

- Whatsapp:+86 13526627860

- Tel: 0086 371 56771823

- Email:oilmachine@doinggroup.com

- Chat Online

Edible oil extraction technology support

- The palm oil mill's FFB-to-CPO process includes: FFB receiving and wei...

- The 50TPD soybean vegetable oil solvent extraction plant usually inclu...

- The soybean oil extraction and refining processes are two complex proc...

- The edible oil pressing method and edible oil solvent extraction metho...

- The key components of groundnut oil press machine mainly include the f...

- There are mainly two different cotton seed oil processing processes on...

- On average, it takes approximately 2.1-2.4 tons of palm kernels to pro...

- The factors to identify the best cooking oil extraction machines for y...

- There are two sunflower oil production processes, sunflower oil produc...

- Basic equipment needed for a groundnut oil commercial production inclu...

Product

Edible oil mill plants projects