Edible oil refining process flow chart and crude edible oil refinery process steps

Edible Oil refining is a complex and flexible work, and a proper refining method must be selected according to the purpose of edible oil refining, taking into account the technical conditions and economic benefits. According to the characteristics of raw materials, edible oil refining methods can be divided into three types, they are mechanical refining, chemical refining and physical chemical refining methods. According to the production capacity and customer's technology requirements, customer's budget the edible oil refining machine can be divided into batch type edible oil refining machine, semi-continuous edible oil refining machine and full continuous edible oil refining machine .

Small scale edible oil refining machine

Small scale edible oil refining machine

The purpose of edible oil refining :

1. Enhance edible oil storage stabilit

2. Improve the flavor of edible oil

3. Improve edible oil color

4. Provide raw materials for edible oil deep processing

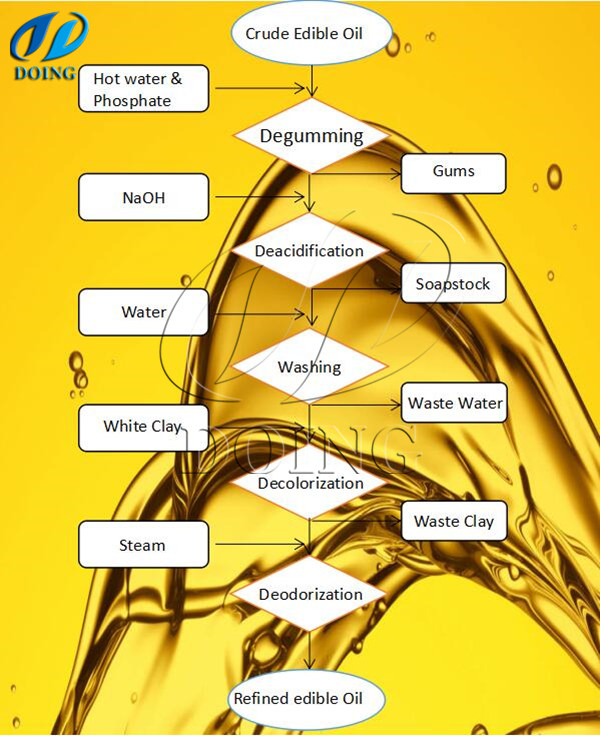

Edible oil refining process flow chart :

Crude edible oil →degumming→deacidification→decolorization→deodorization→refined edible oil

Edible oil refining process flow chart

Edible oil refining process flow chart

Main processes of edible oil refining machine:

Degumming - During palm oil degumming process,we use hydration degumming. The basic principle of edible oil hydration degumming is to use a hydrophilicity of peptized impurities such as phospholipids, and a certain amount of electrolyte solution is added to the oil to cause the colloidal impurities to absorb water and coagulate and separate from the fat.

Deacidification - The existence of free fatty acids makes it difficult to store edible oil for a long time.So the main purpose of edible oil deacidification is to remove free fatty acids from the oil;

Decolorization - Edible oil contains a lot of pigments, which affect the taste and sale of edible oil. In order to get higher edible oil, edible oil decolorization process is a must. At present, the most widely used method is adsorption decolorization, in which some substances with strong adsorption capacity (active white soil, bleach soil, activated carbon, etc.) are added with oil to absorb pigments and other impurities (proteins, mucus, resins, soap, etc.) in the case of heating.

Deodorization - high temperature and high vacuum distillation to remove the unique flavor and bad smell (that is other auxiliary equipment produced during the edible oil refining process;)

Refining effect of edible oil refining machine:

The edible oil after edible oil refining process has transparent color, no sedimentation for a long time, no foaming under the pot, no fumes, and meets the national edible oil standard, which can be directly filled and sold.

Our engineers can help you design and install edible oil refining machine according to your capacity and requirements. More information about edible oil refining machine, you are welcome to come our manufacturing workshop to visit our edible oil refining machine.

- Prev:Edible oil filling machine for edible oil extraction machine

- Next:Rice bran oil extraction process

Leave A Message

If you wanna to get more details about Edible oil refining process flow chart and crude edible oil refinery process steps. you can send E-mail to oilmachine@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- Phone: 0086 13526627860

- Whatsapp:+86 13526627860

- Tel: 0086 371 56771823

- Email:oilmachine@doinggroup.com

- Chat Online

- The palm oil mill's FFB-to-CPO process includes: FFB receiving and wei...

- The 50TPD soybean vegetable oil solvent extraction plant usually inclu...

- The soybean oil extraction and refining processes are two complex proc...

- The edible oil pressing method and edible oil solvent extraction metho...

- The key components of groundnut oil press machine mainly include the f...

- There are mainly two different cotton seed oil processing processes on...

- On average, it takes approximately 2.1-2.4 tons of palm kernels to pro...

- The factors to identify the best cooking oil extraction machines for y...

- There are two sunflower oil production processes, sunflower oil produc...

- Basic equipment needed for a groundnut oil commercial production inclu...