How do we process sunflower seeds in the factory to get sunflower oil?

The oil content of sunflower seeds is about 22%-36% in the whole seeds, 40%-50% in the kernels, and about 1%-2% in the shells, which has a high oil content and is a high-quality raw material for oil extraction. There are two main methods to process sunflower seeds in the factory to get sunflower oil, namely pressing and solvent extraction methods. Next, I will introduce to you how to process sunflower seeds in the factory to get sunflower oil by these methods.

Sunflower oil

Sunflower oil

1. Pressing Method:

Processing sunflower seeds in the factory to get sunflower oil using the pressing method means using mechanical sunflower oil processing machines to extract sunflower oil from sunflower seeds through physical squeezing. The production of sunflower oil using this method mainly includes the following sections:

(1) Cleaning section:

Sunflower seeds contain many impurities. This section can use cleaning machines such as vibrating screens, magnetic separators and destoner to remove debris, stones, metals and other impurities in the sunflower seeds to prevent damage to the sunflower oil processing machines.

Sunflower seeds cleaning machines

Sunflower seeds cleaning machines

(2) Shelling section:

Sunflower seeds have shells, which not only affect the normal operation of the sunflower oil processing machines, but will also absorb some oil, causing oil loss and reducing the oil yield. Therefore, this section needs to use a shelling machine to separate the sunflower seed shells.

(3) Kernel-shell separation section:

The sunflower seed shells and kernels have been mixed together in the above section. After entering this section, a kernel-shell separation screen will be used to separate the sunflower seed kernels and shells to facilitate the subsequent pressing of the sunflower seeds.

(4) Flaking section:

Next, the sunflower seeds need to enter the flaking section, which uses a flaking machine to press the granular sunflower seeds into thin flakes, thereby changing the internal structure of the sunflower seeds, shortening the oil path, and speeding up the oil extraction efficiency.

(5) Cooking section:

In order to achieve the best pressing effect of sunflower seeds, it is necessary to use a cooker to steam the sunflower seeds in advance to adjust the moisture and temperature. Usually the optimum pressing temperature is about 100℃ and the moisture content is about 12%.

(6) Pressing section:

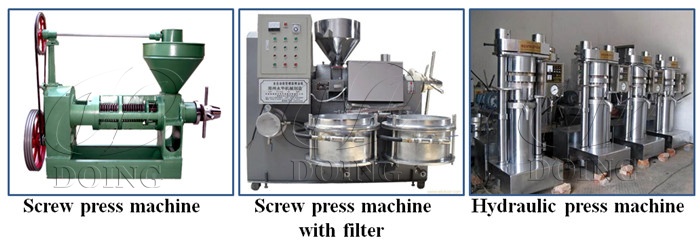

After cooking, the sunflower seeds will enter the pressing section, where we usually use a screw oil press machine to press the oil. It is worth mentioning that Henan Glory Company has more than ten years of experience in the production and manufacturing of screw oil press machines. In addition, according to the different processing capacities of raw materials and the functional characteristics of the oil press machines, the company can not only provide customers with screw oil press machines that can press a variety of plant seeds, but also provide hydraulic oil press machines and automatic temperature control oil press machines, with a residual oil rate of up to 6-7%.

Three types of sunflower oil press machines

Three types of sunflower oil press machines

(7) Filtering section:

The crude sunflower oil produced by pressing section oil residue and many fine impurities, so it needs to enter the filtrating section to remove the oil residue scraper, oil clarification tank and frame and plate filter. The frame and plate filter produced by Henan Glory Company is made of food-grade 304 stainless steel, which can avoid the influence of the filter plate on the quality of sunflower oil.

Frame and plate filter produced by Henan Glory Company

Frame and plate filter produced by Henan Glory Company

2. Solvent Extraction Method:

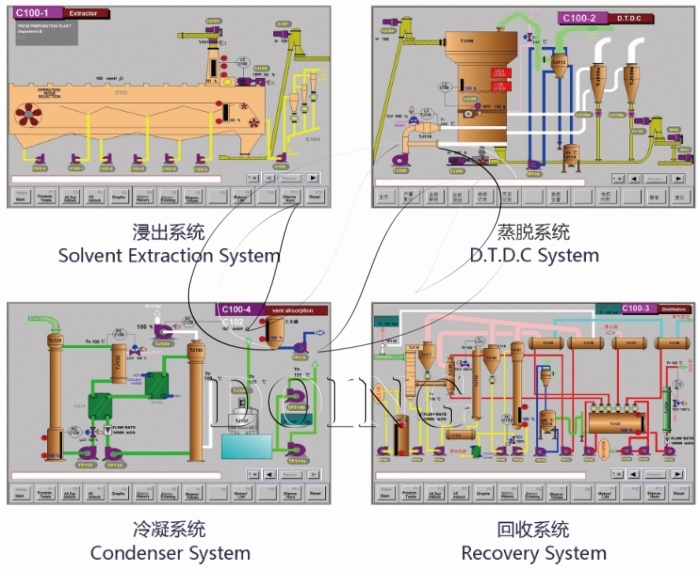

Processing sunflower seeds in the factory to get sunflower oil using the solvent extraction method means the application of chemical extraction principle, using the mutual solubility of solvent and oil, through a long time’s spraying and penetration of solvent and mixed oil to extract the oil into the solvent. Then the oil is extracted by taking advantage of the different boiling points of the oil and the solvent. The production of sunflower oil using this method mainly includes the following sections:

Sunflower oil solvent extraction machines

Sunflower oil solvent extraction machines

(1) Oil solvent extraction section:

The pre-pressed cake of the pre-treated oil is sent to the extractor, The heated solvent and the sunflower oil are fully mixed and after solvent extraction, mixed oil with solvent and wet meal with solvent are obtained.

(2) Miscella evaporating and stripping section:

Taking advantage of the different boiling points of solvent and oil, evaporation and stripping are used to achieve the purpose of fully separating solvent and oil.

(3) De-solventing and baking meal section:

The meal discharged from the extractor contains 25% to 35% solvent. In order to recover the solvent and obtain meal of better quality, DTDC is needed to recover the solvent in the meal through desolventing and drying, while reducing the moisture content in the meal.

(4) Solvent recovery section:

Use condensers, water separators and other machines to recycle solvents and reduce solvent loss in the extracting process. Usually, after extracting and extraction, the oil content of crude oil cake can be reduced to about 1%.

Sunflower oil dewaxing machine

Sunflower oil dewaxing machine

In the end, whether you use pressing method or solvent extraction method to process sunflower seeds in the factory to get sunflower oil, you will get crude sunflower oil. What is more noteworthy is that not only does the sunflower seed itself contain a high amount of wax, but the shells also contain a a high amount of wax. Even after shelling, the sunflower oil obtained must be dewaxed. If you have any questions about the process of processing sunflower seeds in the factory to get sunflower oil or sunflower oil processing machines, please feel free to ask us and we will provide you with professional answers!

- Prev:How to process sunflower seeds into sunflower oil?

- Next:What should be avoided during palm oil production to improve production efficiency and oil quality?

Leave A Message

If you wanna to get more details about How do we process sunflower seeds in the factory to get sunflower oil? . you can send E-mail to oilmachine@doinggroup.com . And you also can leave a message in below form. We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- Phone: 0086 13526627860

- Whatsapp:+86 13526627860

- Tel: 0086 371 56771823

- Email:oilmachine@doinggroup.com

- Chat Online

- The palm oil mill's FFB-to-CPO process includes: FFB receiving and wei...

- The 50TPD soybean vegetable oil solvent extraction plant usually inclu...

- The soybean oil extraction and refining processes are two complex proc...

- The edible oil pressing method and edible oil solvent extraction metho...

- The key components of groundnut oil press machine mainly include the f...

- There are mainly two different cotton seed oil processing processes on...

- On average, it takes approximately 2.1-2.4 tons of palm kernels to pro...

- The factors to identify the best cooking oil extraction machines for y...

- There are two sunflower oil production processes, sunflower oil produc...

- Basic equipment needed for a groundnut oil commercial production inclu...