20tpd peanut oil refining machine

Support to visit cooking oil processing machine factory, supply turn-key projects, provide customized services

Contact us:- Phone/Whatsapp: +86 13526627860

- Email: oilmachine@doinggroup.com

20tpd peanut oil refining machine

20tpd peanut oil refining machine

Usually 20tpd peanut oil refining machine often adopts semi-continuous edible oil refining technology to refine crude peanut oil. After peanut oil degumming, neutralizing, bleaching and deodoring process. The refined oil has high quality and is good for long time storage.

This 20tpd peanut oil refining machine not only refine crude peanut oil , but also refine other crude edible oil, such as rapeseed oil, cotton seed oil, soybean oil, canola oil, palm oil, palm kernel oil, coconut oil, etc. Besides, semi continuous peanut oil refining machine, we also offer 1-10tpd small scale peanut oil refining machine and 30-600tpd fully-continuous peanut oil refining machine.

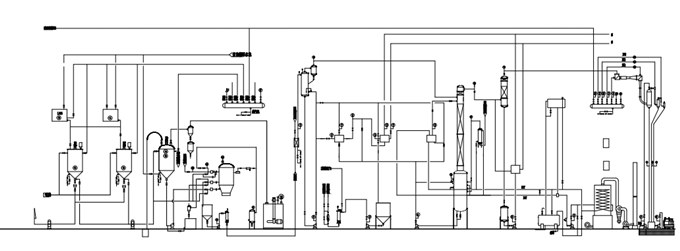

Flow chart of 20tpd peanut oil refining machine:

Flow chart of peanut oil refining machine (this is sem-continuous peanut oil refining process flowchart)

Flow chart of peanut oil refining machine (this is sem-continuous peanut oil refining process flowchart)

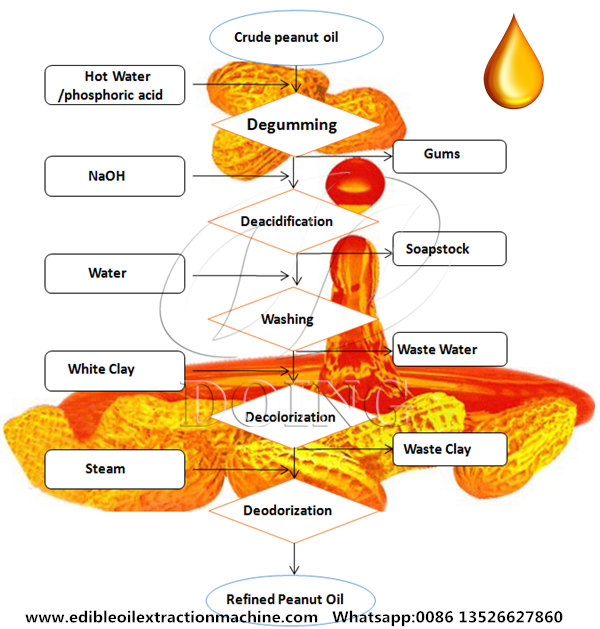

20tpd peanut oil refining process:

Crude peanut oil→ Degumming process → Deacidification process → Decolorization process → Deodorization process → Refined peanut oil (final peanut oil)

Peanut oil refining process flowchart

Peanut oil refining process flowchart

Process of 20tpd peanut oil refining machine:

Degumming process:

The purpose of Degumming is to remove Gums. All oils have hydratable and non-hydratable gums.

a. Water Degumming: Hydratable gums are removed by treating oils with water and separating the gums. The gums can be dried to produce lecithin.

b. Acid Degumming: Non-Hydratable gums are removed by treating oils with acids and separating the gums.

Neutralizing process:

The purpose of Neutralizing is to remove Free-Fatty Acids (FFAs). Traditionally, FFAs are treated with caustic soda (NaOH). The reaction produces Soaps which are separated from the oil. Because trace amounts of soaps remain in the oil, the oil is either washed with water or treated with Silica.

But if you don't want to use caustic soda (NaOH) to remove Free-Fatty Acids (FFAs). You can choose to use physical refining method to dispose FFA. During peanut oil physical refining process, The FFAs in peanut oil are evaporated from the oil under high temperature and vacuum.

Note:

Physical Refining process is preferred because:

(a) it does not produce soaps;

(b) it recovers fatty acids that provide better cost recovery;

(c) there is smaller yield loss compared to caustic refining—especially for oils with higher FFAs;

(d) it is a chemical-free process.

Bleaching process:

The purpose of Bleaching is to remove color pigments contained in Vegetable Oils. The oil is treated with Bleaching Clays that adsorb the color pigments. The clay is filtered and the clean bleached oil is stored for further processing. Process flow diagram is attached.

Deodorizing process

The purpose of Deodorizing is to remove odor substances. The peanut oil is subjected to steam distillation under high temperature and vacuum to evaporate all odor substances. The resulting deodorized oil is almost bland and tasteless.

This is semi-continuous peanut oil refining machine

This is semi-continuous peanut oil refining machine

Why so many people choose to buy peanut oil refining machine from Henan Doing Company?

1. Customized capacity. We customize peanut oil refining machine as per your requirement for the capacity.

2. Flexible usage. The peanut oil refining machine can work independently or together with whole peanut oil production line;

3. Excellent after-sales service. We provide two engineers after your receipt of equipments for on site installation, debugging and training.

As a professional manufacturer and supplier of edible oil refining machine. Henan Doing Company will customize the edible oil refinery process and solution for each of customer depending on their specific situation and needs.

Leave A Message

If you wanna to get more details about 20tpd peanut oil refining machine . you can send E-mail to oilmachine@doinggroup.com . And you also can leave a message in below form. We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- Now,more and more businessman are interested in setting up a mini or s...

- According to different capacity and edible oil refining technology, th...

- The whole set peanut oil processing machine is composed of peanut oil ...

- This continuous peanut oil refining line is designed for continuous op...

- Peanut cake solvent extraction machine is part of peanut oil mill plan...

- What is the Process Flow from FFB to CPO in a Palm Oil Mill?

- What equipment does a 50TPD soybean vegetable oil solvent extraction plant include?

- Comprehensive guide to soybean oil extraction and refining processes

- Is it better to process edible oil by pressing or solvent extraction?

- Key components of groundnut oil press machine