Continuous peanut oil refining line

Support to visit cooking oil processing machine factory, supply turn-key projects, provide customized services

Contact us:- Phone/Whatsapp: +86 13526627860

- Email: oilmachine@doinggroup.com

If your browser can not play the video, you can change the higher version of the browser or download the video to the local broadcast.DOWNLOAD

This continuous peanut oil refining line is designed for continuous operation. Continuous peanut oil refining process always including the following sections: degumming, deacidification, bleaching, deodorizing. In the entire peanut oil refining process, a lot of refining equipments will be used, such as crude peanut oil storage tank, Phosphoric acid tank, centrifugal equipment, bleaching tower, vacuum filter, deodorization tower, FFA catcher, steam boiler, heat contductive oil system, etc. The whole continuous peanut oil refining line adopts the full automatic control system, ensuring the whole peanut oil refining process precision, as well as energy saving, low consumption etc.

Continuous peanut oil refining machine 3D diagram

Continuous peanut oil refining machine 3D diagram

Henan Doing Company is a leading designer, manufacturer and exporter of edible oil refinery plant in both continuous type vegetable oil refinery plant and batch type vegetable oil refinery plant. Next you will see the continuous peanut oil refining process.

It is very essential that the crude oil obtained from oil press workshop and solvent extraction workshop get refined in the vegetable oil refinery plants before it is utilized directly. Our continuous peanut oil refining machine line gives color uniformity and appealing quality to the oil by removing unpleasant smell and undesirable factors from the oil.

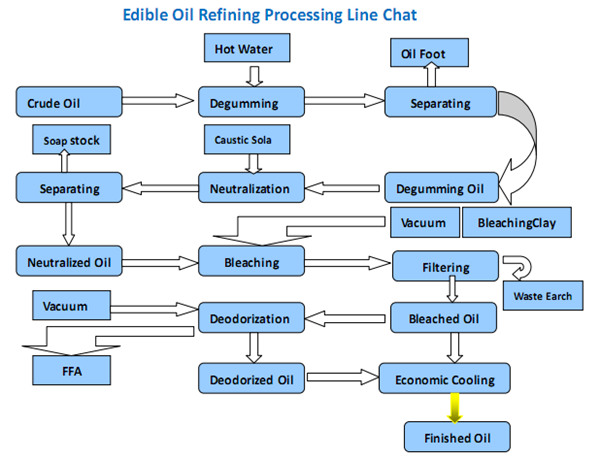

Process flow chart diagram of continuous peanut oil refining machine:

Process flow chart diagram of continuous peanut oil refining machine:

Peanut oil refining machine introduction:

Main equipment: Crude oil filter, Crude oil tank, Crude oil pump, Washing centrifuge,Degumming centrifuge,Vacuum dryer, Hot water tank,Soap-stock tank,Decolorization tower,Decolorization oil pump,Plate filter, Steam super-heater,Decolorizing oil tank, Deodorization tower,Deodorization oil pump,Vacuum system, Vacuum pump, Cooling tower, Thermal oil furnace, PLC automatic controlFunctions of continuous peanut oil refining process:

Peanut oil refining process can remove the different kinds of impurity in the Crude Edible Oil.

Peanut oil refining process can improve the oil quality. Such as the taste, the smell, the colour, the acid value, etc. which affects human consumption.

After peanut oil refining process, the cooking oil is not easy to Oxidize and quality can be promised to store for longer time.

Mian equipment of continuous peanut oil refining machine

Mian equipment of continuous peanut oil refining machine

Mian process of continuous peanut oil refining machine line:

1. Crude peanut oil degumming process

2. Crude peanut oil deacidification/neutralization process

3. Crude peanut oil decolorizing process

4. Crude peanut oil deodorization/distillation(deodorizing unit) process

1>Degumming:Degumming removes gums as preparation for subsequent refining processes.

2>Deacidification:Deacidification removes FFA (free fatty acid) in crude oil.

3>Decolorization: Decolorization removes pigments in crude oil by adding white clay, which can improve the oil quality.

4>Deodorization : Deodorization removes odor in crude oil, which can improve the flavor, stability, color and quality of the oil.

Working principle of continuous penaut oil refining line:

Calibrated crude oil is pumped to pipe filters; then filtered oil is sent to heat exchanger. Heated oil is mixed with acid in the mixer before going to the reaction tank. After reaction and cooling, the oil enters another mixer to mix with caustic alkali liquid to neutralize. The neutralized oil enters the centrifugal to separate soap from peanut oil. Separated oil still contents some quantity of soap that should be removed. By mixing with hot water, the oil is washed. Then a centrifugal is used to separate the water with residual soap from oil.

De-gummed and neutralized peanut oil is pumped into vacuum drier, and then dried oil is cooled by a heat exchanger and sent into a storage tank. De-gummed and neutralized oil is sent to bleaching section to bleach. Oil to be bleached is pumped to mixed tank and heating tank separately. A proportion of oil to be bleached is pumped into a mixing tank to mix with dosed bentonite, and another part of oil to be bleached is pumped to the heater. The mixture and the heated oil go into the bleaching tank to de-colourize. Consequently, the mixture of oil and bentonite is pumped into leaf filter to remove deposable bentonite.

Parallel leaf filters make it possible to perform continuous operation of bleaching. Filtered oil is pumped into the storage tank after being cooled in a heat exchanger and filtered safely.

Deodorization section is to remove the unpleasant odor from bleached peanut oil. Certain amount of citric acid liquid is added to the oil to be deodorized to chelate the metal ion in oil. The oil then enters a deaeration tank to remove air in the oil by high vacuum. Then oil is pumped into a heat exchanger to raise temperature with hot deodorized oil; peanut oil is heated further by mineral oil to raise the temperature to 240℃~265℃. The heated oil goes into the deodorizer tower from the top of flash sector; mixes with the rising steam to strip low molecular organic compound. Oil flows down to the bottom of tower to perform pigment decomposition. The flavor of oil is improved. Oil is pumped into the main sector of deodorizer tower to further remove free fatty acid (FFA). The vapor goes into FFA stripping sector to exchange heat; the condensed low molecular compound goes into the recycling FFA stripping system. The deodorized oil from the bottom of deodorizer tower is pumped out to exchange heat with oil that comes out from the deaeration tank, and then goes to a cooler. Finally, oil is filtered by polished filter. Final product is sent to final oil tank, which can be sold as first class product oil.

Continuous peanut oil refinery plant built by Henan Doing Company

Continuous peanut oil refinery plant built by Henan Doing Company

Economic & technical Index of 50tpd peanut oil refining machine ( degumming, deacidification, bleaching, deodorization)

| Power consumption | ≤28 KWH/ton oil |

| Steam consumption | ≤360~420 Kg/ton oil |

| White earth consumption | ≤8~20 kg/ ton oil |

| Caustic soda | ≤7 kg/ ton oil(according to crude oil acid |

| Phosphoric acid | ≤1.0 kg/ ton oil |

| Water consumption | Circulating water 60~65t/h |

| Water consumption 0.25~0.3t/ton oil |

Our company is specialized in Peanut oil mill plant. We can provide the peanut oil pretreatment and pressing machine, peanut oil solvent extraction plant , peanut oil refining machine. For peanut oil refining machine, the popular capacity is small scale peanut oil refining production line from 1-5 tons ,medium penaut oil refining production line from 5-30 tons and larger capacity peanut oil refining production line from 30-1200tons. If you are interested in peanut oil refining machine, please contact us!

Leave A Message

If you wanna to get more details about Continuous peanut oil refining line. you can send E-mail to oilmachine@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- Now,more and more businessman are interested in setting up a mini or s...

- According to different capacity and edible oil refining technology, th...

- The whole set peanut oil processing machine is composed of peanut oil ...

- This continuous peanut oil refining line is designed for continuous op...

- Peanut cake solvent extraction machine is part of peanut oil mill plan...

- What is the Process Flow from FFB to CPO in a Palm Oil Mill?

- What equipment does a 50TPD soybean vegetable oil solvent extraction plant include?

- Comprehensive guide to soybean oil extraction and refining processes

- Is it better to process edible oil by pressing or solvent extraction?

- Key components of groundnut oil press machine