Batch type peanut oil refinery plant and continuous peanut oil refinery plant

Support to visit cooking oil processing machine factory, supply turn-key projects, provide customized services

Contact us:- Phone/Whatsapp: +86 13526627860

- Email: oilmachine@doinggroup.com

If your browser can not play the video, you can change the higher version of the browser or download the video to the local broadcast.DOWNLOAD

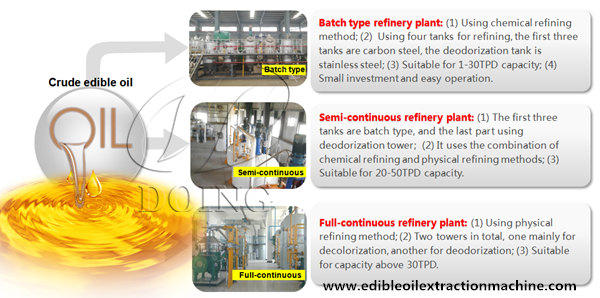

According to different capacity and peanut oil refining technology, the peanut oil refinery plant can be divided into batch type peanut oil refinery plant and continuous peanut oil refinery plant. Basic process of peanut oil refinery is same in both batch & continuous peanut oil refinery. They all includes degumming/neutralizing, bleaching & deodorizing.

Crude peanut oil obtained from peanut oil expellers or peanut oil solvent extraction plant contains foreign impurities such as mucilage, gums, coloured & unfiltered matter from the seed. Also Free Fatty Acids (F.F.A.) which tend to deteriorate the oil on storage, thus we need to peanut oil refinery plant to refine crude peanut oil to high quality edible oil.

Batch type peanut oil refinery plant, semi-continuous peanut oil refinery plant and full-continuous peanut oil refinery plant photo

Batch type peanut oil refinery plant, semi-continuous peanut oil refinery plant and full-continuous peanut oil refinery plant photo

Henan Doing Company is specialized in peanut oil refinery plant. We can provide the peanut oil refinery plant from 1 ton to 1000 tons. In general, batch type peanut oil refinery plant is with capacity 1-20TPD; The semi-continuous peanut oil refinery plant is suggested with capacity from 20-50TPD; And continuous peanut oil refinery plant is used for capacity above 50TPD. Of course, this is just an option, not necessary. Our engineer can help you design the whole peanut oil refinery plant according to your capacity and requirements.

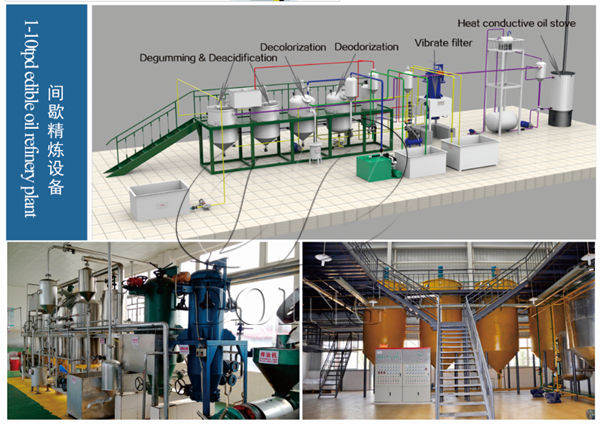

Today we mainly introduce 1-10tpd small scale batch type peanut oil refinery plant and 30-1000tpd continuouspeanut oil refinery plant to you:

Batch type peanut oil refinery plant introduction:

1-10tpd small scale batch type peanut oil refining machine

1-10tpd small scale batch type peanut oil refining machine

1-10tpd small scale peanut oil refining machine is a widely used edible oil refining machine which is suitable for various vegetable and animal oils, such as soybean oil, peanuts oil, sunflower oil, rape seeds oil, cottonseeds oil, coconut oil, rice bran oil, palm oil, palm kernel oil, etc. What's more, batch type peanut oil refinery plant has outstanding features, such as low onvestment cost, easy operation and maintenance, less land request, etc.

The batch type peanut oil refinery process consists of following section :

Degumming process;

Deacidification process ( also named neutralization process);

Bleaching process;

Deodorizing process;

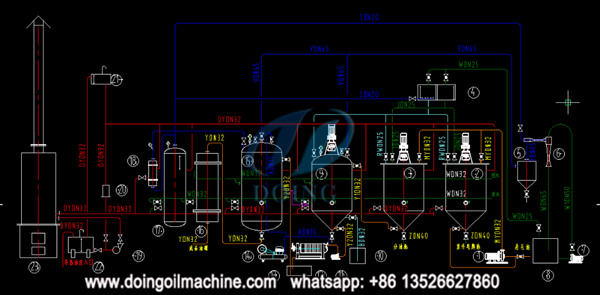

Small scale peanut oil refinery process flow chart

Small scale peanut oil refinery process flow chart

Working priciple of 1-10tpd small scale batch type peanut oil refinery plant:

First Stage of batch type peanut oil refinery process is to remove gums by adding phosphoric acid to crude peanut oil. Second stage of batch type peanut oil refinery process is to Remove Free Fatty Acids(F.F.A.) with caustic Soda. This peanut oil refining process also called Neutralizing Process. The next peanut oil refining process is bleaching process. During peanut oil bleaching process, we usually use bleaching earth and activated carbon to remove colour. Finally it will be deodorized under high vacuum and high temperature to remove the odour from the oil. After above a series of refining process, we can get high quality peanut oil which can meet requirement of International Standard.

Continuous peanut oil refinery plant introduction:

Cotinuous peanut oil refinery plant with capacity (50-600tpd) General speaking, for 30tpd and above, the full-continuous peanut oil refinery plant is much better for large scale edible oil refinery plant. Though the cost of full-continuous peanut oil refinery plant is high, the quality is much more steady and average. The whole peanut oil refining process is totally automatic, which can work continuously and stably.

Cotinuous peanut oil refinery plant with capacity (50-600tpd) General speaking, for 30tpd and above, the full-continuous peanut oil refinery plant is much better for large scale edible oil refinery plant. Though the cost of full-continuous peanut oil refinery plant is high, the quality is much more steady and average. The whole peanut oil refining process is totally automatic, which can work continuously and stably.

Basic stages of the continuous peanut oil refinery process are as below:

Degumming & Neutralizing process;

Bleaching process;

Deodorizing process;

30-1000tpd large scale peanut oil refinery plant workshop

30-1000tpd large scale peanut oil refinery plant workshop

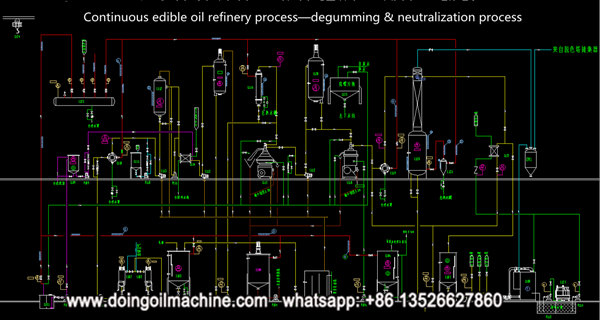

Degumming and neutralization process:

The crude peanut oil is pumped to Neutraliser from peanut oil mill plant or storage tank. First it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums.

Thereafter crude oil is further treated with alkali (NaoH) to remove free fatty acid (F.F.A.) in crude oil. In this process soap will be separated. Next process is use hot water wash the oil to remove traces of soap particle &free alkali.

After peanut oil degumming & deacidification process, we can abtain refined peanut oil also called as washed Neutralised Oil.

Continuous peanut oil refinery process flow chart- degumming and neutralization process

Continuous peanut oil refinery process flow chart- degumming and neutralization process

Bleaching process:

In this process, excess colour will be removed by adding predetermined quantity of bleaching earth & activated carbon.

The neutralized peanut oil is pumped into the decolorization tower with under vacuum. The oil is first heated to remove excess moisture and thereafter it will be treated with predetermined quantity of bleaching earth & activated carbon. Next the decolporized oil will pass through a filter media (Pressure leaf / Filter press) to separate spent bleach earth and bleached oil. Through filtering process, we can get bright light golden appearance peanut oil.

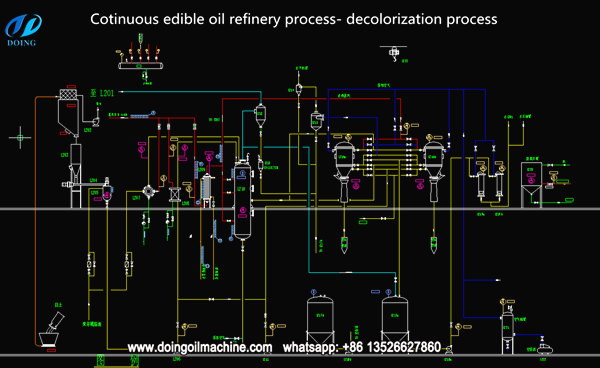

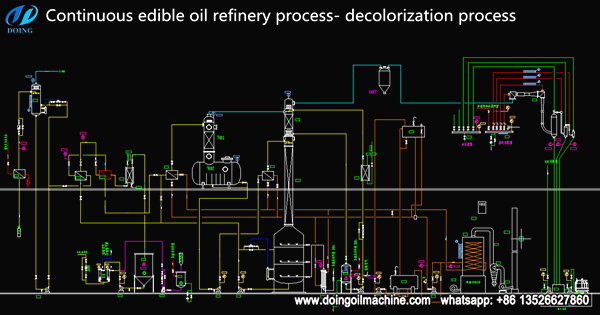

Continuous peanut oil refinery process flow chart- bleaching process

Continuous peanut oil refinery process flow chart- bleaching process

Decolorizing process:

This deodorization process in continuous peanut oil refinery plant mianly used to remove odour from the oil which can improve the quality and self-life of peanut oil.

During peanut oil deodorization process, we use high temperature steam to remove the bad odor from the bleached oil. Once the decolorization process cycle is complete, the oil obtained will be odourless & light in colour. After cooling, the deodorized peanut oil will be sent to polishing filter for further processing. After the process of polishing filter, we can obtained light colour & odourless peanut oil which can be packed for selling.

Continuous peanut oil refinery process flow chart- decodorization process

Continuous peanut oil refinery process flow chart- decodorization process

Our company is specialized in Peanut oil mill plant. We can provide the peanut oil pretreatment and pressing machine, peanut oil solvent extraction plant , peanut oil refining machine. For peanut oil refinery plant, the popular capacity is small scale peanut oil refining production line from 1-5 tons ,medium penaut oil refining production line from 5-30 tons and larger capacity peanut oil refining production line from 30-1200tons. If you are interested in peanut oil refinery plant, please contact us!

Leave A Message

If you wanna to get more details about Batch type peanut oil refinery plant and continuous peanut oil refinery plant. you can send E-mail to oilmachine@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- Now,more and more businessman are interested in setting up a mini or s...

- According to different capacity and edible oil refining technology, th...

- The whole set peanut oil processing machine is composed of peanut oil ...

- This continuous peanut oil refining line is designed for continuous op...

- Peanut cake solvent extraction machine is part of peanut oil mill plan...

- What equipment does a 50TPD soybean vegetable oil solvent extraction plant include?

- Comprehensive guide to soybean oil extraction and refining processes

- Is it better to process edible oil by pressing or solvent extraction?

- Key components of groundnut oil press machine

- How cottonseed oil processing equipment transforms seeds into oil?