Groundnut oil refinery plant

Support to visit cooking oil processing machine factory, supply turn-key projects, provide customized services

Contact us:- Phone/Whatsapp: +86 13526627860

- Email: oilmachine@doinggroup.com

Small scale groundnut oil refinery plant

Small scale groundnut oil refinery plant

Groundnut oil refinery plant is the main equipment of peanut/groundnut oil mill plant. Groundnut oil refinery plant can refine crude groundnut oil and get standard groundnut oil. We are able to supply professional groundnut oil refinery plant to meet different customer's requirements.

The oil obtained from pressing or solvent extraction process always contains impurities such as phospholipids, FFA, pigment, off-flavor and other impurities. In order to make the oil edible, the impurities must be taken out. So the groundnut oil refinery plant is necessary.

Groundnut oil refining process always including the following sections: degumming, neutralizing, bleaching, and deodorizing section. In the entire groundnut oil refining process, a lot of refining equipments can also be used, such as refining pot, bleaching pot, deodorization pot, vacuum filter, heat conduction oil furnace system, etc.

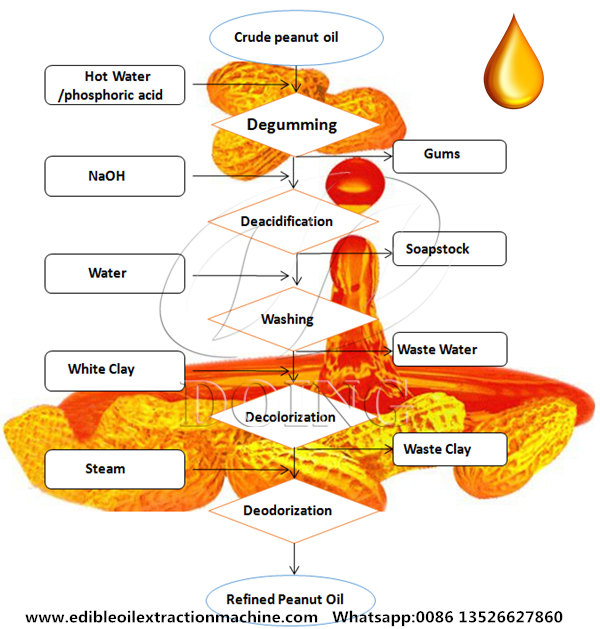

Process flow of groundnut oil refinery process:

Groundnut oil refining process flowchart

Groundnut oil refining process flowchart

Working priciple of groundnut oil refinery plant:

Impurity removal.

Impurity of extracted peanut oil must be removed in order to reduce losses and increase yield of groundnut oil in peanut oil refinery process. Crude oil filter can remove impurities, control impurity of extracted peanut oil under 0.2%, thus improve degumming efficiency.

Degumming:

Intermittent groundnut oil refinery process preheats peanut crude oil to 80 ~ 85 ℃. The amount of water in crude oil bases on colloid content, and generally 3-5 times of the gum content, water temperature at 85 ~ 90 ℃ (5 ℃ higher than oil temperature). Finish water adding in 40-60min, along with 60-70r/min stirring, continue stirring 3-5min after adding water, and stand for precipitation 2-4h.

Vacuum drying:

Heat degummed vegetable peanut oil to 25 ~ 135 ℃, dehydrated into a vacuum dryer 20 ~ 30 min. Moisture of dehydrated oil is less than 0.1% (after degumming of crude oil via the oil contained in the 0.3% to 0.5 % of the water will affect the adsorption capacity of bleaching clay section).

Decolorization:

Degumming of peanut oil can remove grease in oil pigment to improve oil color, adsorption of aflatoxin and trace metals, phospholipids, other gum and other impurities. Decolorization of groundnut oil refinery plant ensures high quality of peanut oil and improves oil stability.

Deodorization:

Control oil temperature to 250 ~ 270 ℃ when decolorized peanut oil enters into deodorizer, in direct steam injection, the free fatty acids, ketones, aldehydes and other impurities are removed from the oil, the thermal decolorized action also occurs, and the pigment composition is cleaved distilled from the oil. Deodorized vacuum (absolute pressure) controlled at 266 Pa, the deodorization time is about 2h.

Henan Doing Company is a professional manufacturer of groundnut oil refinery plant.We provide high quality groundnut oil refinery plant as well as free and skilled technical guidance! Supply various kinds of peanut/groundnut oil mill plant solutions for different customer depends on your customized demands. Premium equipment for peanut oil making machine and peanut oil solvent extraction plant. Welcome to make an order from Henan Doing Company!

Leave A Message

If you wanna to get more details about Groundnut oil refinery plant. you can send E-mail to oilmachine@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- Now,more and more businessman are interested in setting up a mini or s...

- According to different capacity and edible oil refining technology, th...

- The whole set peanut oil processing machine is composed of peanut oil ...

- This continuous peanut oil refining line is designed for continuous op...

- Peanut cake solvent extraction machine is part of peanut oil mill plan...

- What is the Process Flow from FFB to CPO in a Palm Oil Mill?

- What equipment does a 50TPD soybean vegetable oil solvent extraction plant include?

- Comprehensive guide to soybean oil extraction and refining processes

- Is it better to process edible oil by pressing or solvent extraction?

- Key components of groundnut oil press machine