Deacidification process and technology of edible oil

Oil neutralization is another step in the edible oil refining process. Oil neutralization is also known as deacidification. It neutralizes fatty free acids in the oil using caustic soda, thereby converting the acids into soaps. These soaps are easily removed by decantation or by centrifugal force. Since there are many kinds of oilseeds with differing qualities, Henan Doing Company's edible oil refining machine is equipped with versatile technology for the oil neutralization process.

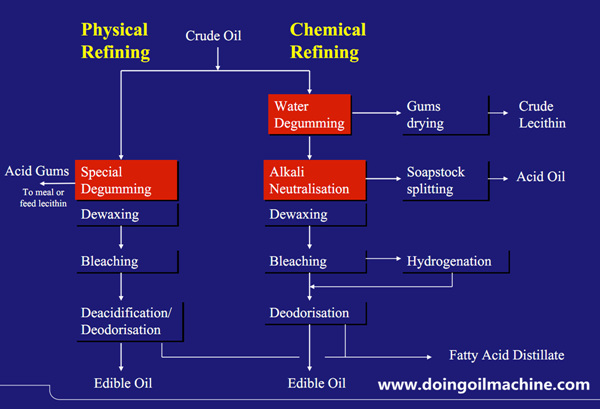

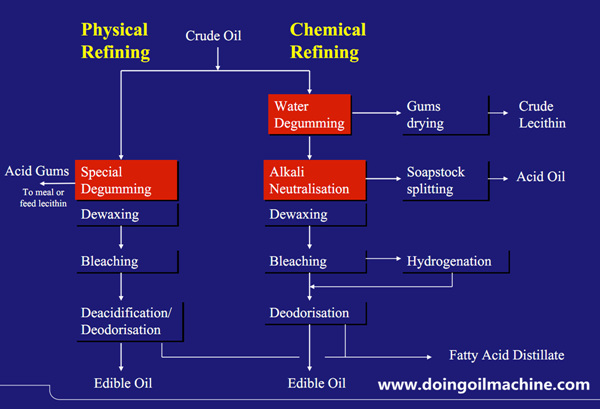

The refining of edible oils requires a series of refining steps, with the most important being the decrease of the free fatty acid level of the crude oil. The crude edible oil deacidification step is very important for the quality of the final product and has a major impact on the economic feasibility of the whole process. Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed (Fig. 1). The names physical and chemical refining come from the process technology used to remove the free fatty acids (FFA) that are responsible for the oil acidity. Physical refining is a process making use of the lower boiling point of the FFA compared to the boiling point of the triglyceride oil. In chemical or alkaline refining, an alkali is used to neutralise the FFA.

Figure 1:physical refining and chemical refining of edible oil

Chemical refining is the traditional method used in past centuries. The main purpose of chemical refining is to saponify the FFA by an alkaline solution and dilute the resulting soaps in a water phase. These soaps are removed by separators. For small-scale batch processes static separation is used but for continuous processing and large-scale processes, centrifugal separation is used. The neutral oils are subsequently bleached and deodorised.

In addition to the removal of FFA other undesirable non-glyceride materials are also removed. These are mainly:

Phospholipids (gums)

Oxidized products

Metal ions (e.g. iron, copper)

Colour pigments (e.g. gossypol)

Insoluble impurities (e.g. meal fines)

The process steps in chemical refining can be adapted in accordance with the crude oil quality to give a good final oil quality with acceptable oil losses.

Working process of Deacidification process (Neutralization process)

Oil phase free of hydratable gums flows to a Centrifugal mixer after heating in a plate heat exchanger, where it is added with phosphoric acid from acid storage tank by a metering pump. The mixture is further taken to a Centrifugal mixer where it is added with caustic lye from lye solution service tank by a metering pump. The caustic solution circuit is completed with storage tank and recirculation pump. The mixture is then taken to a centrifuge where the non-hydratable gums and soap stock are separated and are pumped out of the system by a pump via a soap collecting tank.

Washing:

Oil free of gums and having traces of soapstock is pumped by a pump through a plate heat exchanger where it is heated by steam. Then it is sent to the Centrifugal mixer to be mixed with water and further centrifuged in a centrifuge for water washing. The washed water is then further sent to the slop oil tank for collection and recovery of escaped neutral oil which is then taken back to the system by a pump.

The refining of edible oils requires a series of refining steps, with the most important being the decrease of the free fatty acid level of the crude oil. The crude edible oil deacidification step is very important for the quality of the final product and has a major impact on the economic feasibility of the whole process. Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed (Fig. 1). The names physical and chemical refining come from the process technology used to remove the free fatty acids (FFA) that are responsible for the oil acidity. Physical refining is a process making use of the lower boiling point of the FFA compared to the boiling point of the triglyceride oil. In chemical or alkaline refining, an alkali is used to neutralise the FFA.

Figure 1:physical refining and chemical refining of edible oil

In addition to the removal of FFA other undesirable non-glyceride materials are also removed. These are mainly:

Phospholipids (gums)

Oxidized products

Metal ions (e.g. iron, copper)

Colour pigments (e.g. gossypol)

Insoluble impurities (e.g. meal fines)

The process steps in chemical refining can be adapted in accordance with the crude oil quality to give a good final oil quality with acceptable oil losses.

Working process of Deacidification process (Neutralization process)

Oil phase free of hydratable gums flows to a Centrifugal mixer after heating in a plate heat exchanger, where it is added with phosphoric acid from acid storage tank by a metering pump. The mixture is further taken to a Centrifugal mixer where it is added with caustic lye from lye solution service tank by a metering pump. The caustic solution circuit is completed with storage tank and recirculation pump. The mixture is then taken to a centrifuge where the non-hydratable gums and soap stock are separated and are pumped out of the system by a pump via a soap collecting tank.

Washing:

Oil free of gums and having traces of soapstock is pumped by a pump through a plate heat exchanger where it is heated by steam. Then it is sent to the Centrifugal mixer to be mixed with water and further centrifuged in a centrifuge for water washing. The washed water is then further sent to the slop oil tank for collection and recovery of escaped neutral oil which is then taken back to the system by a pump.

- Prev:Degumming process and technology of edible oil

- Next:Decolorization process and technology of edible oil

Leave A Message

If you wanna to get more details about Deacidification process and technology of edible oil . you can send E-mail to oilmachine@doinggroup.com . And you also can leave a message in below form. We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

Contact us

- Phone: 0086 13526627860

- Whatsapp:+86 13526627860

- Tel: 0086 371 56771823

- Email:oilmachine@doinggroup.com

- Chat Online

Edible oil extraction technology support

- The palm oil mill's FFB-to-CPO process includes: FFB receiving and wei...

- The 50TPD soybean vegetable oil solvent extraction plant usually inclu...

- The soybean oil extraction and refining processes are two complex proc...

- The edible oil pressing method and edible oil solvent extraction metho...

- The key components of groundnut oil press machine mainly include the f...

- There are mainly two different cotton seed oil processing processes on...

- On average, it takes approximately 2.1-2.4 tons of palm kernels to pro...

- The factors to identify the best cooking oil extraction machines for y...

- There are two sunflower oil production processes, sunflower oil produc...

- Basic equipment needed for a groundnut oil commercial production inclu...

Product

Edible oil mill plants projects