Rice bran extruder puffing machine

Support to visit cooking oil processing machine factory, supply turn-key projects, provide customized services

Contact us:- Phone/Whatsapp: +86 13526627860

- Email: oilmachine@doinggroup.com

General Description of rice bran extruder puffing machine :

The rice bran extruder puffing machine is applicable for the extruding of low oil content crops such as rice bran and soybean or pressed cake before solvent extraction,rice bran extruder puffing machine is an ideal production process for the purpose of reducing equipment investment, raising production, reducing energy consumption and improving product quality of oil plants worldwide. There are many kinds of puffing machine, can be divided into soybean oil puffing machine, rice bran oil puffing machine, high oil pre-press oil puffing machine, and tissue proteins oil puffing machine and so on. According to different treatment for different oil seeds. In addition to puffing process, different kinds of oil seeds may also need cooking, softening, flaking , drying and other processes to get the most oil yield and meal of better quality.

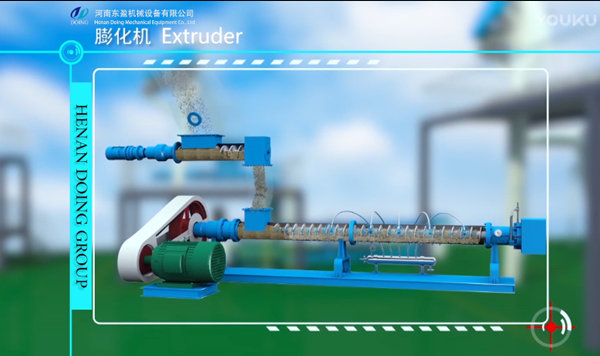

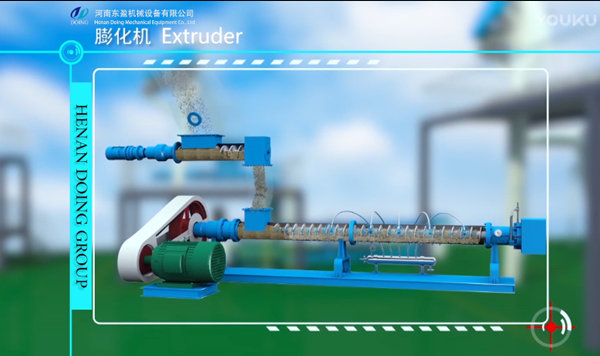

Extruder puffing section of rice bran pretreatment and pressing workshop

Adopting the rice bran extruder puffing machine can both improve the yield of rice bran oil and reduce the consumption. The extrusion puffing, on the one hand, can make solution lipase in the rice bran passivated under high temperature and high pressure condition, then prevent the rice bran oil rancidity; On the other hand, the extrusion puffing can make rice bran be porous material grain, and increases the materials bulk density, then improve the permeability and leaching rate which solvent reacts to the material.

Rice bran oil mill plant we have installed

Working principle of rice bran extruder puffing machine:

The oil material is squeezed, heated, sheared and rubbed in the extruding cavity of the machine, and mixed,Steamed, gelatinized by injected direct steam, the pressure in extruding cavity will reach 1.4-4.0 MPa, the temperature reachs 110-120º C, at the die head outlet suddenly reduce to normal pressure and temperature, the steam vaporizes abruptly, oil in seed cell run outside then, and extruded material with numberless minus holes and cracks got. And because of such extruding effects, the permeating of solvent through cells and permeating of oil out from cells both become easier, so the extraction and desolventizing process both get more efficient, the unit weight of material is raised about 30%, so the production capacity of extractor is also raised. The stay period of material in the extruding machine is less than 30 seconds, so the damage of the content of material is little, which helps the protection of the quality of material.

Detail show of rice bran extruder puffing machine

Mian features of rice bran extruder puffing machine:

1. Improving production capacity of extractor

Bulk density of extruded materials increases 20%--30% than this of raw cake, so process capacity of extractor and desolventizer-toaster is improved.

2. Improving extraction speed, reducing extraction time

Cell structures of extruded materials are destroyed completely, microhole number of extruded materials is increased, so penetrability which solvent and mixed oil pass through materials layers is improved.

3. Solvent content of wet meal is lowered, reducing load of wet meal desolventization.

Because of good penetrability and drying, solvent content of wet meal can be lowered to 20% or so. Loads of wet meal desolventization and solvent recovery are reduced, so steam consumption of wet meal desolventization is saved.

4. Improving mixed oil concentration, lowering load of mixed oil steaming

Mixed oil concentration is improved from 20% or so to 28—30%, saving steam consumption of mixed oil steaming process.

5. Enzymes of oil materials are passivated, improving extracted crude oil quality

Enzymes and anti-nutritional factors of oil materials are passivated, which avoids lipoxygenase and phospholipid enzyme effect on phospholipid of oil materials, reduces non-hydrated phospholipid content of extraction crude oil, and increases total phospholipid content of extraction crude oil. So oil refining efficiency is improved, oil product quality is also improved, as well phospholipid by-products output and phospholipid product quality are increased in hydrated degumming section.

6. Improving output of germ pressing equipment

In expanding extraction section, it isn’t strict for thickness of raw germ, thickness of rolling germ may lower requires adequately, so output increases.

7. Lowering power consumption in extraction process section

Mixed oil concentration is improved,and solvent content of wet meal is lowered, which reduces efficiently solvent consumption. Improvement of production capacity makes production cose lower.

8. Simple operation

Rice bran oil pretreatment and pressing workshop

Main Technical Parameters of the rice bran extruder puffing machine

DY series rice bran expander extruder machine technical parameters:

We welcome your further inquiry, expecting to provide you with a complete solution.For different oil seeds, processing equipments change. We can help you design complete set of rice bran oil making machine according to your material and final product. If you want to know more about rice bran extruder puffing machine , please do not hesitate to contact us.

The rice bran extruder puffing machine is applicable for the extruding of low oil content crops such as rice bran and soybean or pressed cake before solvent extraction,rice bran extruder puffing machine is an ideal production process for the purpose of reducing equipment investment, raising production, reducing energy consumption and improving product quality of oil plants worldwide. There are many kinds of puffing machine, can be divided into soybean oil puffing machine, rice bran oil puffing machine, high oil pre-press oil puffing machine, and tissue proteins oil puffing machine and so on. According to different treatment for different oil seeds. In addition to puffing process, different kinds of oil seeds may also need cooking, softening, flaking , drying and other processes to get the most oil yield and meal of better quality.

Extruder puffing section of rice bran pretreatment and pressing workshop

Adopting the rice bran extruder puffing machine can both improve the yield of rice bran oil and reduce the consumption. The extrusion puffing, on the one hand, can make solution lipase in the rice bran passivated under high temperature and high pressure condition, then prevent the rice bran oil rancidity; On the other hand, the extrusion puffing can make rice bran be porous material grain, and increases the materials bulk density, then improve the permeability and leaching rate which solvent reacts to the material.

Rice bran oil mill plant we have installed

Working principle of rice bran extruder puffing machine:

The oil material is squeezed, heated, sheared and rubbed in the extruding cavity of the machine, and mixed,Steamed, gelatinized by injected direct steam, the pressure in extruding cavity will reach 1.4-4.0 MPa, the temperature reachs 110-120º C, at the die head outlet suddenly reduce to normal pressure and temperature, the steam vaporizes abruptly, oil in seed cell run outside then, and extruded material with numberless minus holes and cracks got. And because of such extruding effects, the permeating of solvent through cells and permeating of oil out from cells both become easier, so the extraction and desolventizing process both get more efficient, the unit weight of material is raised about 30%, so the production capacity of extractor is also raised. The stay period of material in the extruding machine is less than 30 seconds, so the damage of the content of material is little, which helps the protection of the quality of material.

Detail show of rice bran extruder puffing machine

Mian features of rice bran extruder puffing machine:

1. Improving production capacity of extractor

Bulk density of extruded materials increases 20%--30% than this of raw cake, so process capacity of extractor and desolventizer-toaster is improved.

2. Improving extraction speed, reducing extraction time

Cell structures of extruded materials are destroyed completely, microhole number of extruded materials is increased, so penetrability which solvent and mixed oil pass through materials layers is improved.

3. Solvent content of wet meal is lowered, reducing load of wet meal desolventization.

Because of good penetrability and drying, solvent content of wet meal can be lowered to 20% or so. Loads of wet meal desolventization and solvent recovery are reduced, so steam consumption of wet meal desolventization is saved.

4. Improving mixed oil concentration, lowering load of mixed oil steaming

Mixed oil concentration is improved from 20% or so to 28—30%, saving steam consumption of mixed oil steaming process.

5. Enzymes of oil materials are passivated, improving extracted crude oil quality

Enzymes and anti-nutritional factors of oil materials are passivated, which avoids lipoxygenase and phospholipid enzyme effect on phospholipid of oil materials, reduces non-hydrated phospholipid content of extraction crude oil, and increases total phospholipid content of extraction crude oil. So oil refining efficiency is improved, oil product quality is also improved, as well phospholipid by-products output and phospholipid product quality are increased in hydrated degumming section.

6. Improving output of germ pressing equipment

In expanding extraction section, it isn’t strict for thickness of raw germ, thickness of rolling germ may lower requires adequately, so output increases.

7. Lowering power consumption in extraction process section

Mixed oil concentration is improved,and solvent content of wet meal is lowered, which reduces efficiently solvent consumption. Improvement of production capacity makes production cose lower.

8. Simple operation

Rice bran oil pretreatment and pressing workshop

Main Technical Parameters of the rice bran extruder puffing machine

| Raw Materials | Soybean, Rice Bran, Rapeseed |

| Thickness of Flaking | 0.35~0.45mm |

| Moisture Content before Extruding | 10~11% |

| Moisture Content after Extruding | 12~13% |

| Discharge Temperature | 105~110℃ |

| Steam Pressure | 0.65~0.75Mpa |

| Steam Temperature | 174.5℃ |

DY series rice bran expander extruder machine technical parameters:

| Technical specifications | Capacity(t/d) | Screw Diameter (mm) | Steam pressure (Mpa) | Power of Main Motor (KW) | Discharge Temperature(℃) |

| DYP16 Expander | 30~80 | 1:1.2~1.4 | 0.6~0.8 | 37/55 | 100~120 |

| DYP20 Rice Bran Expander | 50~200 | 1:1.2~1.4 | 0.6~0.8 | 55/75 | 100~120 |

| DYP25 Rice Bran Expander | 150~400 | 1:1.2~1.4 | 0.6~0.8 | 75/90 | 100~120 |

| DYP30 Rice Bran Expander | 300~600 | 1:1.2~1.4 | 0.6~0.8 | 90/110 | 100~120 |

| DYP35 Rice Bran Expander | 400~900 | 1:1.2~1.4 | 0.6~0.8 | 110/132 | 100~120 |

We welcome your further inquiry, expecting to provide you with a complete solution.For different oil seeds, processing equipments change. We can help you design complete set of rice bran oil making machine according to your material and final product. If you want to know more about rice bran extruder puffing machine , please do not hesitate to contact us.

Leave A Message

If you wanna to get more details about Rice bran extruder puffing machine. you can send E-mail to oilmachine@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

Rice Bran Oil Extraction Machine

- As a professional manufacturer of rice bran oil processing machine. Be...

- The rice bran extruder puffing machine is applicable for the extruding...

- Integrated rice bran oil press machine is a combined oil expeller equi...

- Rice bran oil making machine is the main machine to produce rice bran ...

- Rice bran Oil Refinery Plant can remove unhealthy impurities such as p...

Product

Edible oil extraction technology support

- What equipment does a 50TPD soybean vegetable oil solvent extraction plant include?

- Comprehensive guide to soybean oil extraction and refining processes

- Is it better to process edible oil by pressing or solvent extraction?

- Key components of groundnut oil press machine

- How cottonseed oil processing equipment transforms seeds into oil?

Edible oil mill plants projects