Soybean oil solvent extraction plant

Support to visit cooking oil processing machine factory, supply turn-key projects, provide customized services

Contact us:- Phone/Whatsapp: +86 13526627860

- Email: oilmachine@doinggroup.com

Soybean seeds contain an average of 17 percent to 20 percent oil. The most popular method for recovering soybean oil is soybean prepress-solvent extraction. Today we mainly introduce the soybena oil solvent extraction plant.

What is the soybean oil solvent extraction plant ?

The soybean oil solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

More specifically say, solvent extraction is a method of making edible oil by using a solvent which can dissolve oil and grease, through contacting with the oil (soaking or spraying), so that the oil and grease in the oil can be extracted.

Daily treatment : 30T, 50T, 80T,100T,150T, 200T, 300T, 450T, 600T, 800T. ..2000T. (Consider the economic benefits, Henan Doing Company's cooking oil processing machine engineers suggest that customers could choose to buy soybean oil solvent extraction plant when the production capacity is over 30tpd. In other words, if your production capacity is small, buying soybean oil solvent extraction plant is not so cost-effective.)

Soybean oil solvent extraction plant

Soybean oil solvent extraction plant

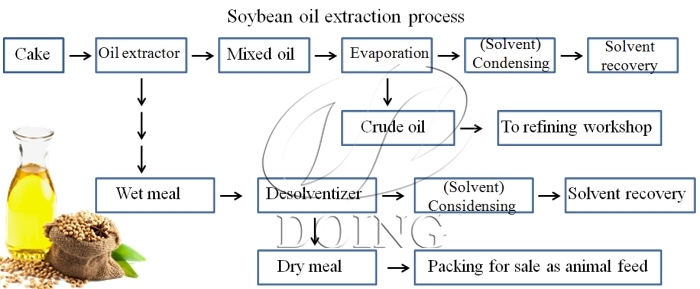

The process flow chart of soybean oil solvent extraction plant:

Soybean oil solvent extraction process flowchart

Soybean oil solvent extraction process flowchart

Main equipment of soybean oil solvent extraction plant:

Solvent pumps: continuously spray solvent to the rotary-type extractor

Rotocel extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and micella (mixed oil).

DTDC: Used to separate the solvent from the wet meal.

Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water,at last the reactant precipitate, reaching the goal of purifying.

Miscella tank 2nd: the purified miscella will be pumped into it.

Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Soybean oil solvent extraction plant

Soybean oil solvent extraction plant

Craft features of soybean oil solvent extraction plant:

1,Whole soybean oil solvent extraction plant adopting negative pressure evaporation can ensure excellent oil quality;

2,extraction system is highly adaptable,and can adapt to different oilseeds;

3,unique exhaust gas absorption systems ensure good absorption effect;

4,full energy-saving design utilize heat energy for many times and saves steam consumption.

Cooking oil extraction plant project :

40tpd soybean oil solvent extraction plant project is installing

40tpd soybean oil solvent extraction plant project is installing

We are the reputed manufacturer, exporter, and supplier of soybean oil solvent extraction plant. To meet every client’s requirements, we offer a wide range of soybean oil solvent extraction plant of different capacities of 30-1000tons. More information, welcome to contact us!

Leave A Message

If you wanna to get more details about Soybean oil solvent extraction plant. you can send E-mail to oilmachine@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- The soya bean oil processing line is a process of obtaining more soya ...

- During the whole soybean oil processing process, the soybean oil proce...

- Henan Doing Company is specialized in soybean oil refining machine. We...

- Soybean oil pretreatment & prepressing machine is the first step to pr...

- The integrated soybean oil press machine with filter has the advantage...

- What is the Process Flow from FFB to CPO in a Palm Oil Mill?

- What equipment does a 50TPD soybean vegetable oil solvent extraction plant include?

- Comprehensive guide to soybean oil extraction and refining processes

- Is it better to process edible oil by pressing or solvent extraction?

- Key components of groundnut oil press machine