Deodorization process and technology of edible oil

Deodorization process is a major part of edible oil refining process, edible oil deodorization process is mainly used to get rid of unpleasant smell from the refined bleached edible oil. Deodorization is primarily a high-temperature, high-vacuum, steam-distillation process.

Crude forms of edible oils are deodorized via steam distillation to evaporate all odor substances and leave the oil with a stable flavor profile.

Effective deodorization is a complex vacuum steam distillation process that involves using high-pressure steam to heat the oil to a precise temperature for stripping impurities and then cooling it to retain the natural oil characteristics. Closed loop, hermetically sealed, high-pressure steam systems that provide tight control over time and incorporate economizers to recover as much heat as possible from the hot oil ensure process stability and save energy.

Deodorization workshop of edible oil

Oil deodorization is the final stage in an edible oil refinery. It creates a more bland oil by removing odiferous material and other minor undesired particles, in turn increasing its shelf life. Oil Deodorizer Tower applies to soybean oil, cotton seed oil, rapeseed oil, camellia seed oil, corn germ oil, rice bran oil, sunflower seed oil, edible oil processing.

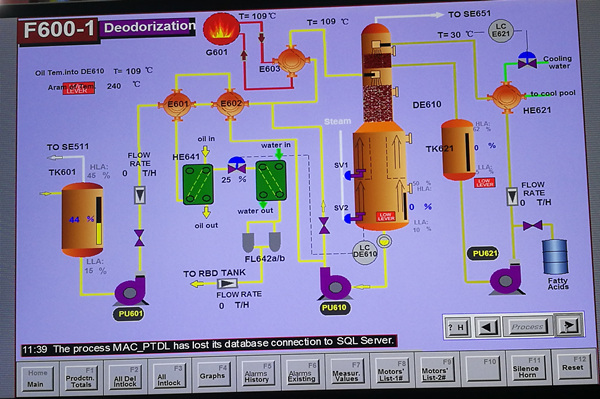

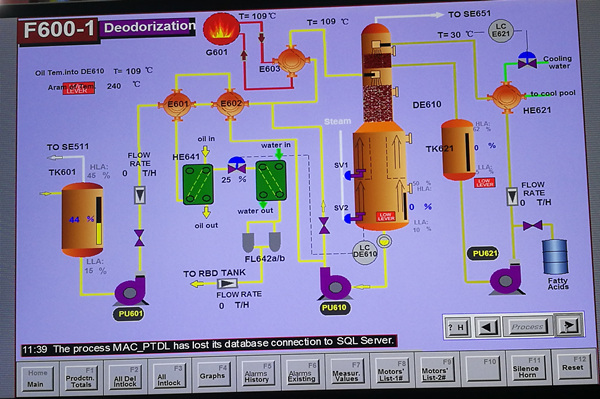

Deodorization process flow chart of edible oil:

Deodorization process flow chart of edible oil

Deodorization Equipment List:

1.Oil supplying pump for Deodorization

2.Deodorized oil pump

3.Fatty acid cycle pump

4.Deodorized oil Cooler

5.Fatty acid Cooler

6.Conduction oil heater

7.Oil to oil heat exchanger

8.Polishing filter

9.Vacuum deaerator

10.Fatty acid cycle tank

11.De-acidification Deodorizing tower

12.steam jet pump

13.Sechanical vacuum pump

14.Mechanical vacuum pump

15.Steam jet pump

16.Seal water tank

17.Steam distribution cylinder

18.Water distributor

19.Cyclic water pump

20.Cooling water pump

21.Cool water tower

22.Heat conduction oil boiler system

23.Expansion joint

We are professional manufacturer of edible oil refinry plant for many years in China, will supply you the most efficient and beneficial equipments for you. Have any question for the edible oil refining process could let us know at any time, we will give you the most suitable proposal.

Crude forms of edible oils are deodorized via steam distillation to evaporate all odor substances and leave the oil with a stable flavor profile.

Effective deodorization is a complex vacuum steam distillation process that involves using high-pressure steam to heat the oil to a precise temperature for stripping impurities and then cooling it to retain the natural oil characteristics. Closed loop, hermetically sealed, high-pressure steam systems that provide tight control over time and incorporate economizers to recover as much heat as possible from the hot oil ensure process stability and save energy.

Deodorization workshop of edible oil

Oil deodorization is the final stage in an edible oil refinery. It creates a more bland oil by removing odiferous material and other minor undesired particles, in turn increasing its shelf life. Oil Deodorizer Tower applies to soybean oil, cotton seed oil, rapeseed oil, camellia seed oil, corn germ oil, rice bran oil, sunflower seed oil, edible oil processing.

Deodorization process flow chart of edible oil:

Deodorization process flow chart of edible oil

Deodorization Equipment List:

1.Oil supplying pump for Deodorization

2.Deodorized oil pump

3.Fatty acid cycle pump

4.Deodorized oil Cooler

5.Fatty acid Cooler

6.Conduction oil heater

7.Oil to oil heat exchanger

8.Polishing filter

9.Vacuum deaerator

10.Fatty acid cycle tank

11.De-acidification Deodorizing tower

12.steam jet pump

13.Sechanical vacuum pump

14.Mechanical vacuum pump

15.Steam jet pump

16.Seal water tank

17.Steam distribution cylinder

18.Water distributor

19.Cyclic water pump

20.Cooling water pump

21.Cool water tower

22.Heat conduction oil boiler system

23.Expansion joint

We are professional manufacturer of edible oil refinry plant for many years in China, will supply you the most efficient and beneficial equipments for you. Have any question for the edible oil refining process could let us know at any time, we will give you the most suitable proposal.

Leave A Message

If you wanna to get more details about Deodorization process and technology of edible oil . you can send E-mail to oilmachine@doinggroup.com . And you also can leave a message in below form. We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

Contact us

- Phone: 0086 13526627860

- Whatsapp:+86 13526627860

- Tel: 0086 371 56771823

- Email:oilmachine@doinggroup.com

- Chat Online

Edible oil extraction technology support

- The palm oil mill's FFB-to-CPO process includes: FFB receiving and wei...

- The 50TPD soybean vegetable oil solvent extraction plant usually inclu...

- The soybean oil extraction and refining processes are two complex proc...

- The edible oil pressing method and edible oil solvent extraction metho...

- The key components of groundnut oil press machine mainly include the f...

- There are mainly two different cotton seed oil processing processes on...

- On average, it takes approximately 2.1-2.4 tons of palm kernels to pro...

- The factors to identify the best cooking oil extraction machines for y...

- There are two sunflower oil production processes, sunflower oil produc...

- Basic equipment needed for a groundnut oil commercial production inclu...

Product

Edible oil mill plants projects