What are the key equipment needed for vegetable oil processing plant?

In generally, a vegetable oil processing plant includes all the equipment required in complete vegetable oil processing technology. But it will varie greatly depending on the capacity, the vegetable oil processing technology, the equipment configuration and customer's budget. So our engineers will give different solutions which includes different key equipment for different customers.

Next, we will take the key equipment of a complete vegetable oil processing plant as an example to introduce the function of each machine and the vegetable oil processing technology.

The complete vegetable oil processing plant

The complete vegetable oil processing plant

The vegetable oil processing technology includes the following processes: raw material cleaning, raw material pre-treatment, oil pressing, crude oil refining, dewaxing, filtration, finished oil. Each process requires different equipment. So the key equipment used in the vegetable oil processing plant includes: vibrating screen, stone remover, crusher, steaming cooker, oil extraction equipment, oil refining equipment, dewaxing equipment, filter equipment, as well as some auxiliary equipment.

The the function of key equipment used in the vegetable oil processing plant:

1. Vibrating Screen: Removes impurities from raw materials such as plant fibers and stones. Under the combined action of wind and vibration, the grain is cleaned of impurities.

2. Stone Remover: Based on the principle of specific gravity, the stone remover moves the sand and stones to the stone discharge hole and separates them, and the grain flows out from the clean grain outlet.

3.Crusher: A machine that uses mechanical actions such as extrusion, shearing, impact and grinding to crush larger oilseed kernels and press cakes into smaller particles. Oilseed kernels with larger particles must be crushed to a suitable particle size. This makes it easier to roll the workpieces in subsequent processes and ensures uniform humidity and temperature control to produce quality workpieces.

Vegetable oil processing equipment

Vegetable oil processing equipment

4. Steaming Cooker: Steaming and frying in a pan. Steaming and frying of oil materials refers to the process in which the green body becomes cooked through processes such as humidification, heating, steaming and frying. The purpose of steaming and frying is to thicken the oil and create conditions for increasing the oil yield, adjusting the organizational structure of the workpiece and bringing the plasticity and elasticity of the workpiece into compliance with the requirements of pressing using moisture and temperature; improve the quality of crude oil and reduce the burden of crude oil processing.

5. Oil Extraction Equipment: At present, two types of oil presses and leaching equipment are commonly used. Oil presses are divided into two categories: screw oil presses and hydraulic oil presses, which are suitable for hot and cold pressing process respectively. Leaching equipment is suitable for the processing capacity of above 30 tons per day vegetable oil processing plant, which has high oil extraction rate and high production efficiency.

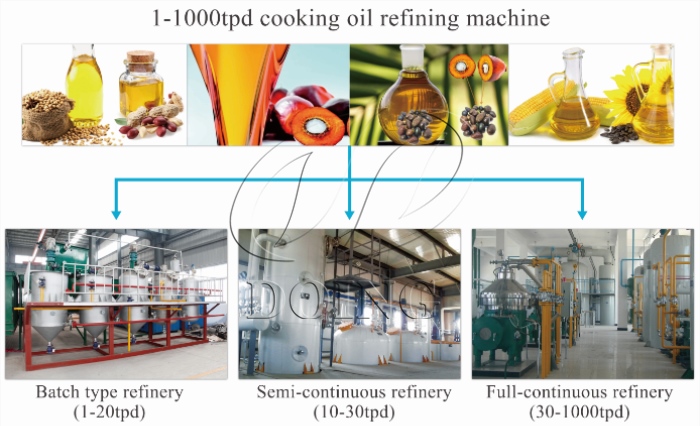

6. Oil Refining Equipment: Crude oil is refined through degumming, decolorization, decolorization, deodorization and other processes to remove impurities and harmful substances from crude oil, to improve the quality of the oil and ensure the food safety of the oil. The oil refining equipment has three types: batch oil refining equipment, semi-continuous oil refining equipment and continuous oil refining equipment.

Three kinds of vegetable oil refining equipment

Three kinds of vegetable oil refining equipment

7. Dewaxing Equipment & Filter Equipment: The edible oil dewaxing process is based on the difference in melting points between wax and oil and the fact that the solubility of wax in oil becomes less as the temperature decreases, and crystalline wax precipitates when cooled. Then through the filter separation surface to achieve the purpose of separating wax and oil. Commonly used equipment in oil plants are plate and frame filters.

The above is a brief introduction to the key equipment in vegetable oil processing plant. The reasonable configuration of the production line is closely related to the subsequent production income. Therefore, when you want to invest in vegetable oil processing plant, you must find a professional manufacturer.

During the communication process, you had better clearly communicate their specific needs to the manufacturer, such as raw materials, production volume, location, etc. The manufacturer accurately offers equipment configuration plans and pricing based on needs. If you want to know more about the equipment details and production line configuration plans, please send us a private message or leave a message. We will provide you with free equipment plans and recommendations.

- Prev:What are the methods and equipment for edible oil solvent extraction?

- Next:Why palm oil extraction machines are the key to determining palm oil quality?

Leave A Message

If you wanna to get more details about What are the key equipment needed for vegetable oil processing plant? . you can send E-mail to oilmachine@doinggroup.com . And you also can leave a message in below form. We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- Phone: 0086 13526627860

- Whatsapp:+86 13526627860

- Tel: 0086 371 56771823

- Email:oilmachine@doinggroup.com

- Chat Online

- The palm oil mill's FFB-to-CPO process includes: FFB receiving and wei...

- The 50TPD soybean vegetable oil solvent extraction plant usually inclu...

- The soybean oil extraction and refining processes are two complex proc...

- The edible oil pressing method and edible oil solvent extraction metho...

- The key components of groundnut oil press machine mainly include the f...

- There are mainly two different cotton seed oil processing processes on...

- On average, it takes approximately 2.1-2.4 tons of palm kernels to pro...

- The factors to identify the best cooking oil extraction machines for y...

- There are two sunflower oil production processes, sunflower oil produc...

- Basic equipment needed for a groundnut oil commercial production inclu...