Small scale sunflower oil refining machine

Support to visit cooking oil processing machine factory, supply turn-key projects, provide customized services

Contact us:- Phone/Whatsapp: +86 13526627860

- Email: oilmachine@doinggroup.com

Small scale sunflower oil refining machine belongs to batch type edible oil refining machine, the common capacity is 1-10tpd. The small scale sunflower oil refining machine has all the advantages of large and medium-sized edible oil refining machine. Since small scale sunflower sunflower oil refining machine is characterized by low investment, small footprint and easy operation and maintenance, now more and investors are tend to invest in sunflower oil refining business. Almost every month there are customer come to visit our small scale edible oil refining plant model machine.

Small scale sunflower oil refining machine

Small scale sunflower oil refining machine

Why sunflower oil need to be refined?

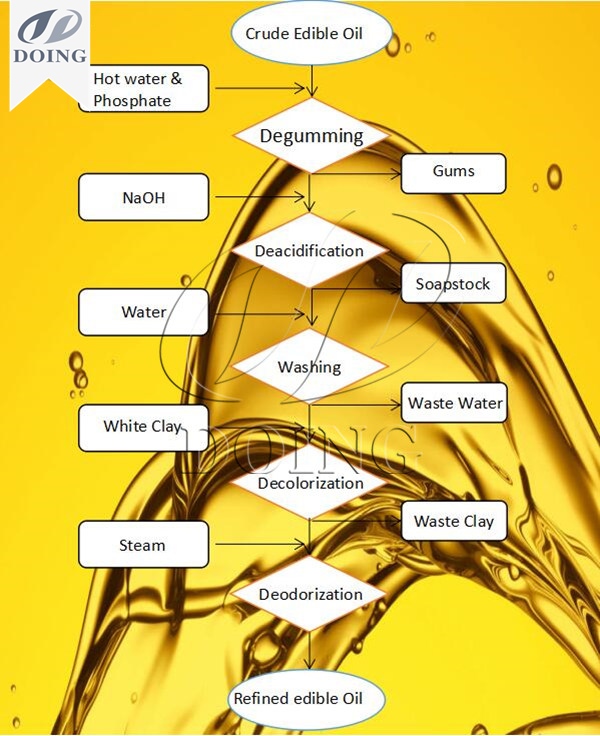

Crude sunflower oil obtained from sunflower oil expeller machine or sunflower oil solvent extraction plant contains some impurities such as mucilage, gums, also Free Fatty Acids (F.F.A.) which must be removed to make the oil edible and suitable for storage. Small scale sunflower oil refining machine is specially designed to remove unhealthy impurities in crude sunflower oil, the whole sunflower oil refining process consisits of sunflower oil degumming process, deacidification process, decolorization process and deodorization process.

Sunflower oil refining process flow chart:

crude sunflower oil → degumming → deacidification → decolorization → deodorization →refined sunflower oil → dewaxing process → edible sunflower oil

Sunflower oil refining process flow chart

Sunflower oil refining process flow chart

Detail introduction of small scale sunflower oil refining machine:

Degumming process:

First Stage of sunflower oil refining process is to Remove gum by adding hot water (there is a little P-acid in water) .

Deacidification process;

Second stage of sunflower oil refining process is deacidification process also named neutralizing process. Using alkali like (NaOH) to neutralize FFA in oil, during this process it will produce soapstock , then separating it from the oil.

Decolorization process:

Third stage of sunflower oil refining process is decolorization process. Because there is pigment in crude oil, the oil color is dark. In order to lighten oil color, we need to using the white clay to absorb the pigment away, then using vibrating filter to separate the waste clay. If you want to get light color oil, you need to add more white clay. the oil color can be controlled by clay amount.

Deodorization process:

The finally stage of sunflower oil refining process is deodorization process. General speaking , the crude oil smells not good, it will affect of oil storage and price. So we usually use the direct steam to take odors. At the meanwhile, there is about 0.5% water content in refined oil, because the high temperature in the deodorization pot, dehydration is also finished. After that, the final oil will be refined once again through safety filter.

Sunflower oil dewaxing process:

Due to the special nature of sunflower oil, after sunflower oil refining process, we also need a dewaxing process to remove the wax from the cooking oil. conventional methods that rely on frozen crystals dewaxing, then separated by mechanical means oil, wax, without adding any auxiliary agents and auxiliary means dewaxing processes.

Technical parameters of small scale sunflower oil refining machine:

| Steam consumption | 700KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Water (soften water) | 150Kg/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Alkali | acid valuex1-3kg/T oil |

| Circulating water cooling water yield | 150M3/ |

| Bleaching earth consumption | 3-5Kg/T oil |

| Waste bleaching earth oil content | ≤25~35% |

| Refining losses |

acid valuex1.2 (chemical refining)

acid valuex 0.6 (physics refining) |

| Bleaching losses | the quantity of bleaching earth×0.25% |

| Deodorization loss consumption | ≤0.5%≤0.5% |

| Refining rate | 1-refining consumption |

Small scale sunflower oil refining machine photos:

Small scale sunflower oil refining machine

Small scale sunflower oil refining machine

Successfully edible oil refinery plant projects in Indonesia:

This efficient 5tpd palm oil physical refinery plant was built in Indonesia to produce high quality edible palm oil. This 5tpd palm oil physical refinery plant consists of palm oil refining pot , palm oil decolorization pot, leaf filter press machine, palm oil deacidification & deodorization tower, heat conduction oil furnace and so on. And the palm oil refinery plant adopts semi-continuous palm oil refinery machinery, which can minimize the investment cost while keeping good performance.

[Related reading: 5tpd palm oil physical refinery plant successfully installed in Indonesia]

5tpd palm oil physical refinery plant successfully installed in Indonesia

5tpd palm oil physical refinery plant successfully installed in Indonesia

Henan Doing Company have rich experience in edible oil refining process, If you want to set up a small scale sunflower oil refinery plant, you are in the right place, Henan Doing Company will supply suitable sunflower oil refining solutions for you according to your production capacity and budget.Related reading: How much it would cost to set up a sunflower oil refinery plant in Uzbekistan?]

Leave A Message

If you wanna to get more details about Small scale sunflower oil refining machine. you can send E-mail to oilmachine@doinggroup.com. And you also can leave a message in below form. We will back to you ASAP once we got your message.

- The sunflower oil filling machine is the auxiliary equipment of the sh...

- Small scale sunflower oil refining machine belongs to batch type edibl...

- Doing Group offered sunflower oil processing machine is used to extrac...

- Integrated sunflower oil press machine with filter is a kind of superi...

- Sunflower oil making machine is the main machine to produce sunflower ...

- What is the Process Flow from FFB to CPO in a Palm Oil Mill?

- What equipment does a 50TPD soybean vegetable oil solvent extraction plant include?

- Comprehensive guide to soybean oil extraction and refining processes

- Is it better to process edible oil by pressing or solvent extraction?

- Key components of groundnut oil press machine